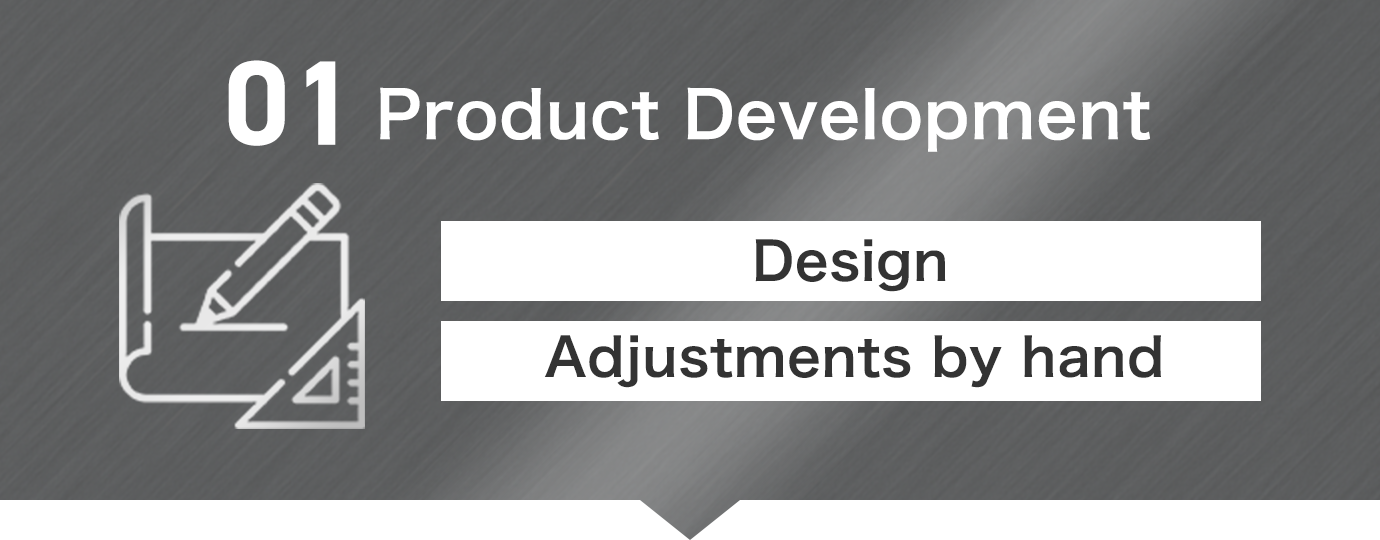

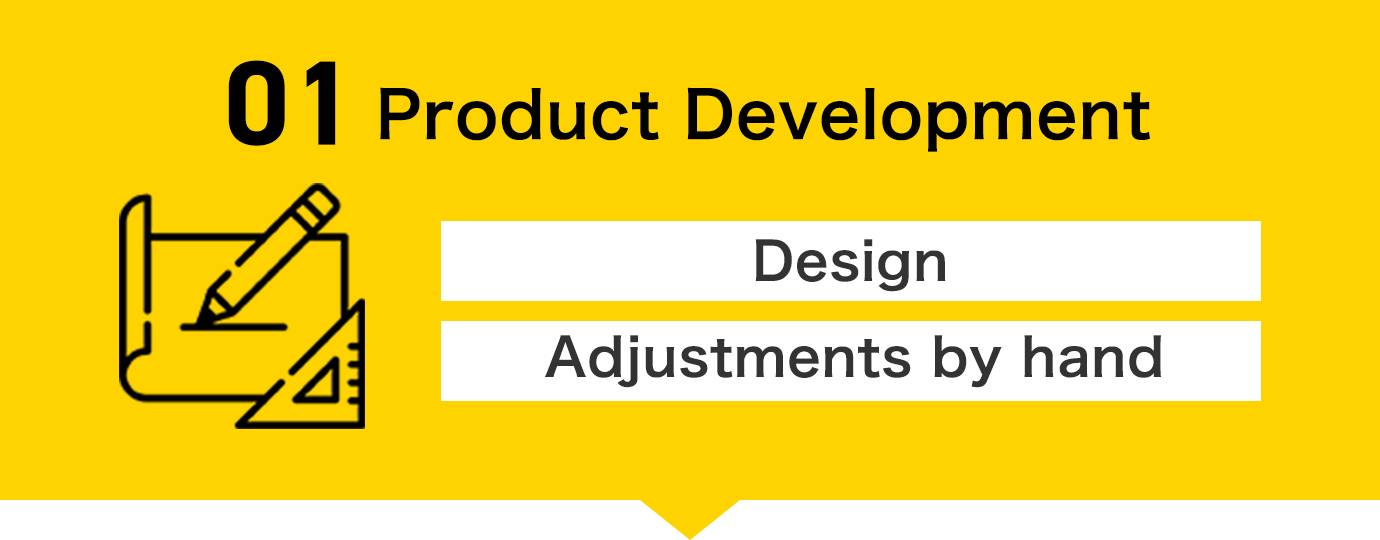

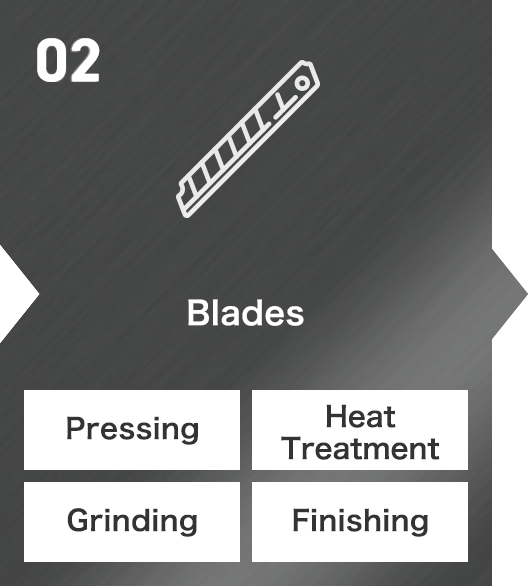

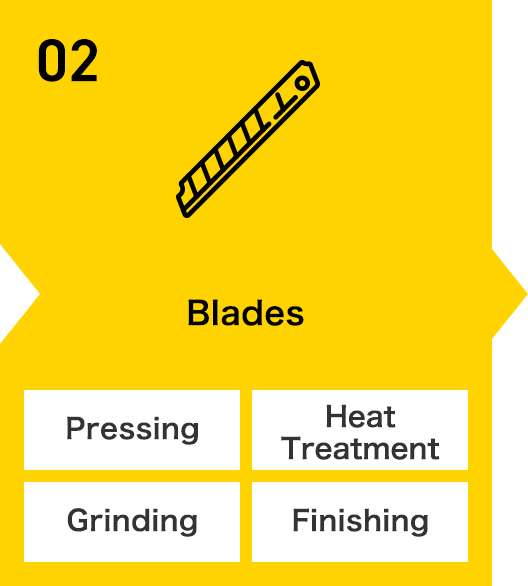

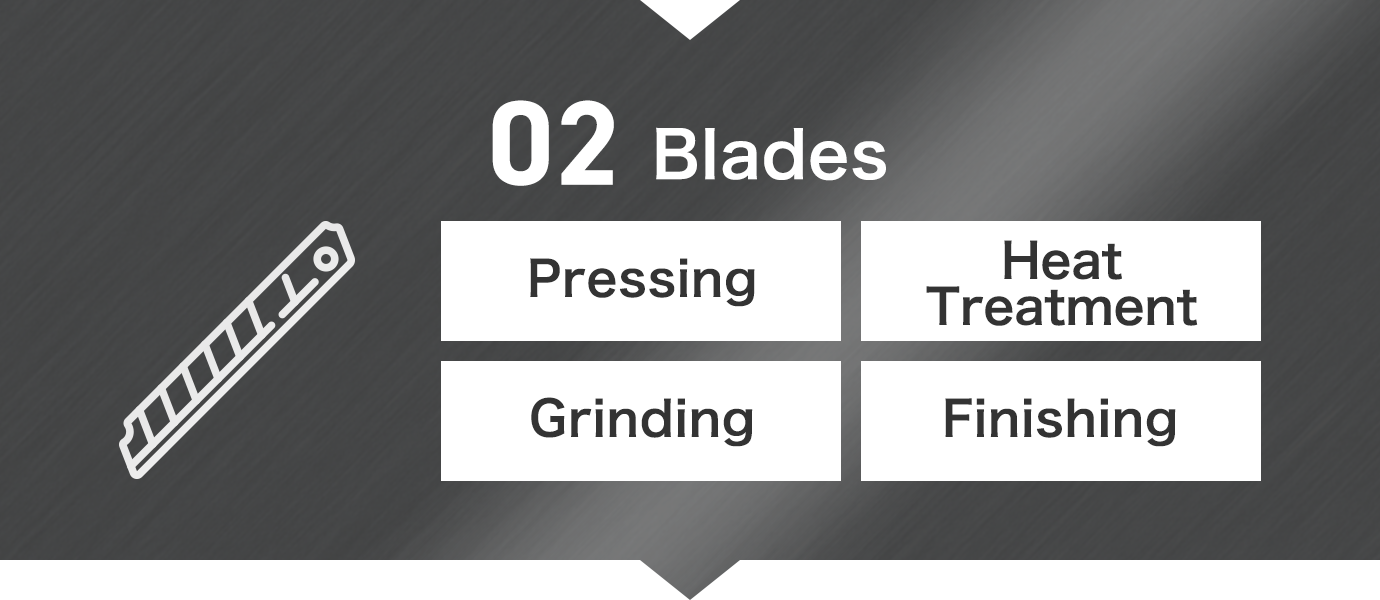

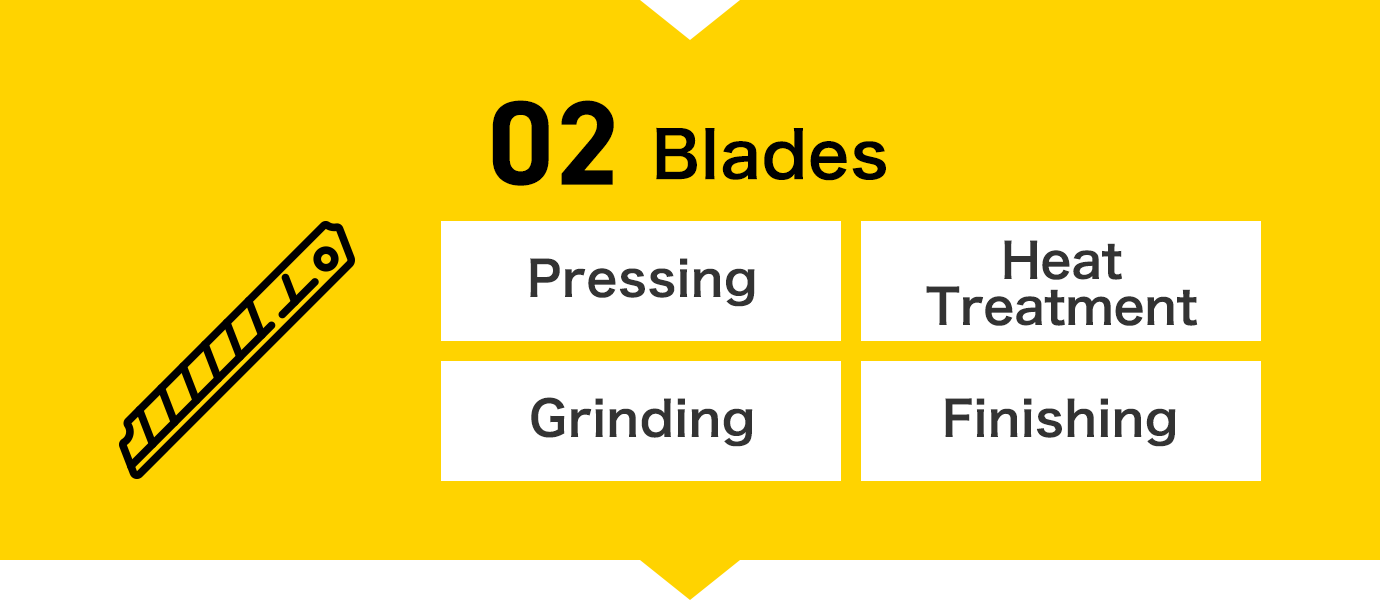

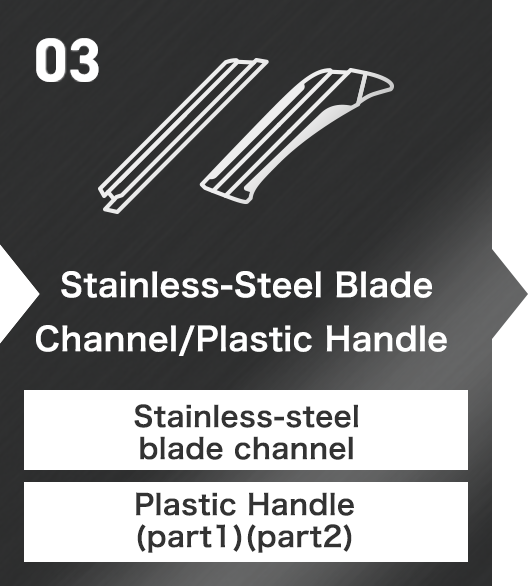

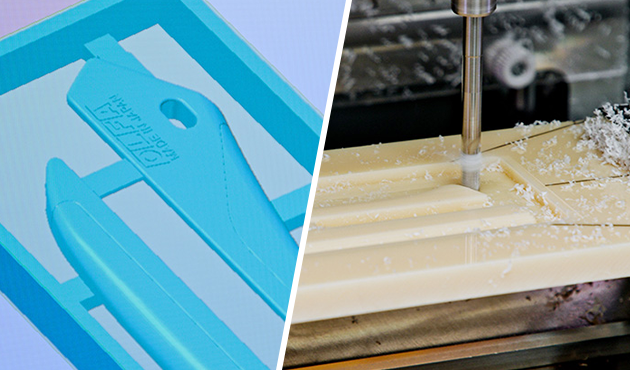

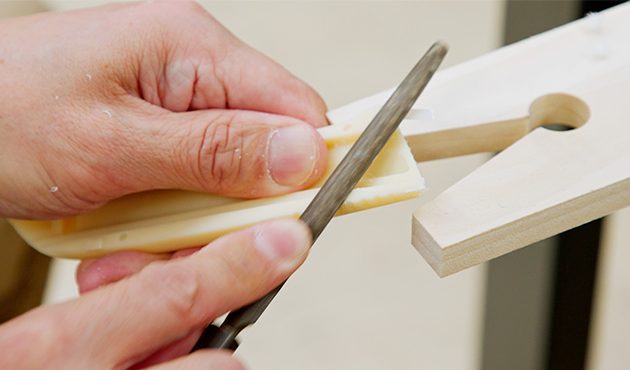

How OLFA cutters

are made

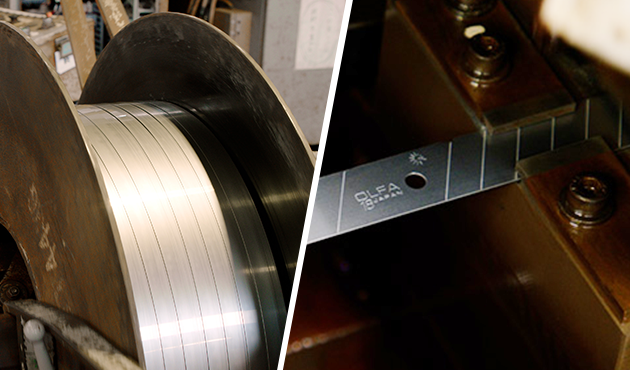

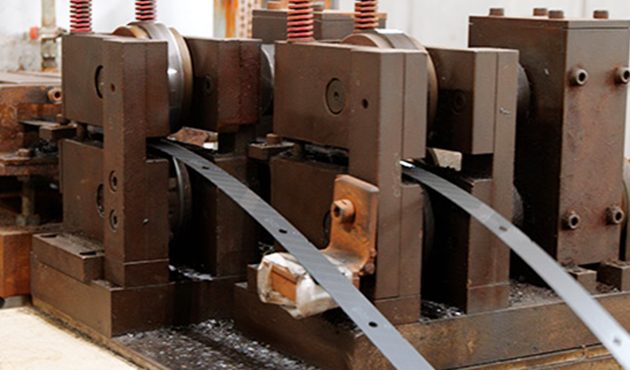

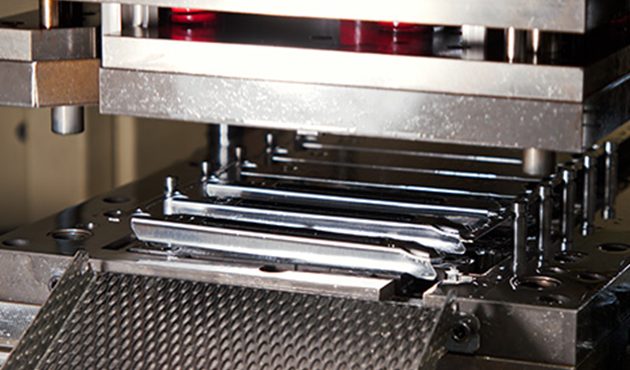

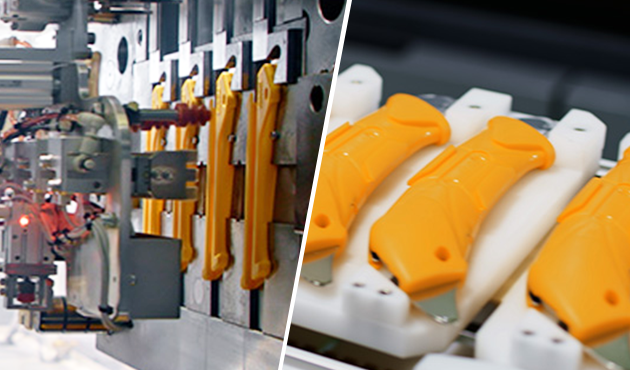

OLFA cutters are manufactured through a variety of processes before being delivered to our customers.

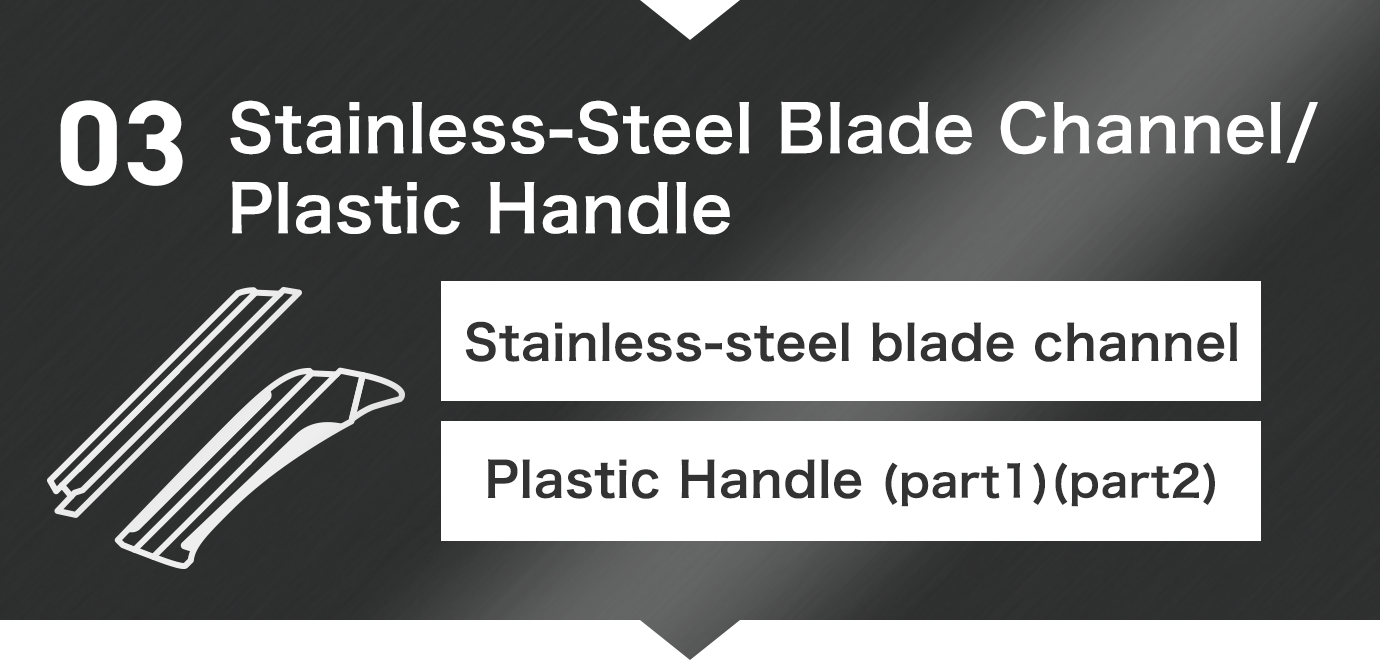

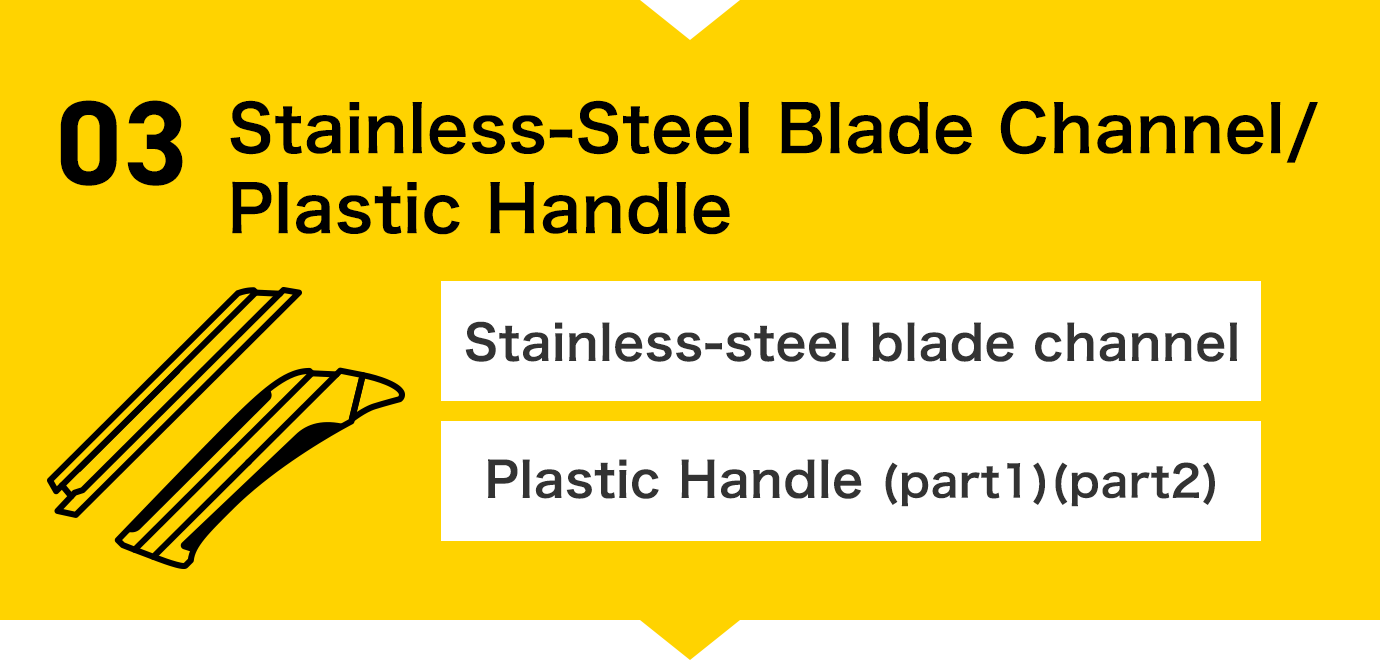

Here let us introduce the manufacturing process of our L-5, one of our most popular products.

OLFA cutters are manufactured through a variety of processes before being delivered to our customers. Here let us introduce the manufacturing process of our L-5, one of our most popular products.